Quality control in CNC machining – how do we ensure precision at SIM Gdynia?

There is no room for compromise in modern industrial production, which is why quality control in CNC machining is the foundation of every project carried out at our plant. At SIM Gdynia, based on over 45 years of experience, we know that even the most advanced machining centres require rigorous supervision to guarantee the highest quality of mechanical components. The role of a quality controller in CNC machining A quality controller at SIM Gdynia is a person who links the design documentation with the actual detail. Their work begins long before the finished component is shipped. They are a partner to the machine setter – it is the controller who decides whether the first piece in a batch meets strict technical standards. In our practice, this process is dynamic: the controller receives the part, takes measurements and provides feedback to the production department. If the dimensions are within tolerance, the “green light” is given for the entire series. If any deviations are detected, the inspector indicates the necessary corrections, which helps to avoid material losses and ensures operational continuity. Such close cooperation between departments is crucial for building the company’s authority as a reliable supplier. From calipers to “gates” – the quality control process at our production plant The selection of measuring tools depends on the complexity of the part’s geometry and the required precision. At SIM Gdynia, we use a technological process that allows us to validate even the most demanding orders. Measuring instrument Technical application Role in the process Digital calliper Workshop measurements, verification of basic linear dimensions. Quick inter-operational control at the machine. Height gauge Precise determination of height, distance between planes and hole axes. Verification of parts with a more complex vertical structure. Mitutoyo CMM machine 3D coordinate measurements for complex solids and curves. Final validation of parts with the highest degree of difficulty and dimensions up to 1000 kg. Our measuring machine allows us to digitally map the geometry of a detail and compare it with a CAD model. This ensures that every hole, thread or milling is exactly where the engineer planned it to be. Before starting the machining process, we often perform a spectrometric analysis of the chemical composition of the materials, which eliminates the risk of using raw materials that do not comply with the specifications. Step-by-step control process In accordance with the principle of continuous optimisation, quality control at SIM Gdynia is a closed, multi-stage process: Implementing this sequence of actions allows us to minimise the risk of products that do not meet production specifications. Summary Quality control is not just a dry measurement of dimensions – it is a comprehensive production risk management strategy. At SIM Gdynia, the inspector guarantees that the components leaving our plant will work reliably for years to come. By combining experienced staff with modern Mitutoyo metrology technology, we provide solutions that build a lasting competitive advantage for our customers. Do you want to be sure that your components will be manufactured with the highest precision? Contact our experts and find out how our control procedures can support your project.

CNC machining changeovers – how to reduce errors and quality losses?

CNC machining is a process in which every minute of downtime directly affects the profitability of production and the unit cost of the finished part. At SIM Gdynia, based on over 45 years of experience in the mechanical component manufacturing industry, we know that the most critical moment for maintaining operational fluidity is retooling in CNC machining. It is at the stage of changing the product range that the greatest number of errors can occur, which can result not only in material loss but also in tool damage. In the following article, we present specific technological solutions that we use in our daily practice to minimise the risk of errors when setting up machines. Why is changeover a production bottleneck? From a technical point of view, retooling in CNC machining is the sum of the activities necessary to prepare the machine to produce the first correct part from a new series. Industry statistics indicate that inefficient setup procedures can consume a significant portion of the machine’s available working time, which we consider to be a structural error in production management. The most common errors and their technical consequences – know-how from the SIM Gdynia production hall The table below presents a summary of the problems most commonly faced by operators and the methods of eliminating them that we have implemented at SIM Gdynia as part of our quality optimisation strategy. Type of error Technical cause Quality effect SIM Gdynia solution Incorrect tool offset Manually enter the corrector into the tool table. Spindle collision or “undersized” workpiece. Automatic measuring probes. Contamination of the base Chip residue under the vice or chuck. Runout error and lack of surface flatness. High-pressure cleaning procedure. Incorrect choice of tooling Use of flexible chucks with high cutting force. Vibrations and poor surface quality. Selection of rigid, dedicated clamping systems in technology. Error in the NC (Numerical Control) programme Outdated version of the so-called post-processor (digital translator of instructions for the machine). Damage to the tool upon first contact with the material. Mandatory simulation of the tool path in a virtual CAM environment before start-up. Eliminating these technical errors allows for the implementation of a rigorous process, which at SIM Gdynia forms the “backbone” of every operation and guarantees the highest quality and precision without unnecessary material losses. SMED optimisation: How do we reduce machine downtime? Effective CNC machining requires the division of activities into internal operations (performed when the machine is idle) and external operations (prepared while the spindle is running). The goal of SMED optimisation is to move as many tasks as possible to the external group. At SIM Gdynia, the preparation of tools in holders, their measurement and the collection of technical documentation takes place while the machine is still executing the previous order. Our experience shows that this approach significantly reduces downtime, which directly translates into shorter lead times for our customers. Key steps in the error reduction process: First-Off quality control – a guarantee of repeatability At SIM Gdynia, we do not start serial production without fully verifying the first piece. This is a critical moment when we check the linear dimensions and surface roughness, ensuring that the machine settings guarantee a basis for any further processes. If the parameters are consistent with the documentation, we start the series, confident that each subsequent detail will be perfectly prepared for final refinement. However, dimensional precision alone is often only half the battle – in the medical or defence industries, the final part must be free of micro-burrs and meet stringent visual standards. You can read more about the finishing process for mechanical components in our article “Surface finishing after CNC machining“. Summary and conclusions Effective CNC machining is a multidimensional process in which attention to detail at the setup stage determines the stability of the entire production. In order to permanently reduce quality losses, it is necessary to focus on three pillars: Are you planning to manufacture complex mechanical components and looking for a partner who takes full responsibility for the quality of the process? Contact us and receive a quote based on optimised manufacturing technologies.

Spectrometric analysis in CNC machining – why is verification of the chemical composition of the material critical?

In modern industrial production, the CNC machining process does not begin when the spindle is started, but much earlier – at the raw material quality control stage. At SIM Gdynia, we use spectrometric analysis, which is a key link here and guarantees that the chemical composition of the delivered metal is 100% compliant with the metallurgical certificate. In this way, we eliminate the risk of introducing raw material with lower strength parameters into the production process, ensuring that the material meets the exact specifications required in our customer’s design. What is spectrometric analysis of materials? At our CNC machining facility, we do not rely solely on suppliers’ paper documentation, because the reliability of raw materials is the foundation of safety. We verify every material relevant to the project using a stationary SPECTROMAXx spectrometer, which utilises optical emission spectrometry (OES) technology. This process involves generating a spark between the electrode and the metal sample being tested, which leads to the emission of light of different wavelengths. The device’s optical system, equipped with high-resolution sensors, analyses this spectrum, allowing the full chemical composition of the alloy to be precisely determined within a few seconds. Thanks to the device’s advanced tenth-generation optics, we can define not only the content of the main elements, such as carbon, chromium and nickel, but also trace amounts of phosphorus, sulphur and nitrogen. At SIM Gdynia, based on over 45 years of experience, we know that it is these microelements that determine whether the material will retain its weldability and corrosion resistance in extreme operating conditions. 3 key reasons for testing the chemical composition of materials in CNC machining Success in positioning product quality is not a matter of chance, but of a rigorous process. Material verification is standard practice in professional CNC machining because it helps to: Information architecture and security – how does the verification process affect the final price? Many decision-makers wonder whether additional testing of the chemical composition of materials increases the unit cost of a part. Yes, but the cost of testing is negligible compared to the losses resulting from the production of a series of 1,000 defective components made of the wrong alloy. At SIM Gdynia, we make sure that the most important control processes are not “hidden deep” in the production structure, but are an integral and easily accessible part of it. You can read more about the device we use in our production plant in the article: “SpectroMaxx spectrometer – what it is and how it revolutionises the testing of the chemical composition of metals“. The most common mistakes in material selection and how to avoid them Errors in the selection of metal grades can have disastrous consequences for business. The most common problem is ignoring the so-called “material gap” – a situation in which the designer assumes steel parameters that are not 100% reproducible by commercially available alloys. Regular technical audits of the raw material allow us to detect these discrepancies at an early stage. Another mistake is not taking into account finishing processes, such as anodising or hardening, which react differently depending on the precise concentration of alloying additives. Spectrometric analysis gives us the certainty that these processes run smoothly. Summary Verification of chemical composition is the foundation of modern CNC machining. At SIM Gdynia, we combine traditional craftsmanship with technology to deliver components of proven quality. Thanks to spectrometry, our customers in the automotive, defence, medical and energy industries can be sure that every gram of metal meets their stringent standards. Do you need safe mechanical components with a material guarantee for your next project? Consult our engineers.

CNC machining in practice – SIM Gdynia in the TVP3 Gdańsk programme “Zawodowcy”

On a daily basis, we focus on stable processes, quality and timely production. This time, however, we had the opportunity to take a break from our daily work routine and look at our CNC machining from a slightly different perspective – that of a television camera. We had the pleasure of participating in the Zawodowcy programme, broadcast on TVP3 Gdańsk. The programme crew visited our plant to show what modern mechanical component production looks like in practice – from the technological background to the daily work of the team. CNC production “from the inside” CNC machining is often associated exclusively with machines and automation. However, the reality of production is much more complex. During the recording, we were able to present the entire process of manufacturing parts – from technology preparation, through tool and parameter selection, to quality control. The camera accompanied us on the production floor, where we carry out turning, milling and more complex multi-axis operations. We showed how important process stability, repeatability of operations and operator experience are, especially in series production and for parts with high quality requirements. The people behind the technology One of the important elements of the episode was the presentation of the daily work of CNC technicians and operators. Modern machinery is essential, but without a competent team, predictable and safe production is impossible. The material clearly shows that CNC machining is a team effort – requiring precision, responsibility and continuous process control. These are the aspects we tried to show the viewers of the “Zawodowcy” programme. We encourage you to watch the episode The episode featuring SIM Gdynia is available online. We encourage you to watch the material and take a look behind the scenes of our daily work: https://gdansk.tvp.pl/90312497/odc-01122025-technik-mechanik We would like to thank the TVP3 Gdańsk team for their visit and the opportunity to show what modern CNC machining looks like in practice at SIM Gdynia.

Serial production in CNC machining – how to reduce costs without compromising quality

Serial production in CNC machining very quickly verifies all technological decisions. What works acceptably in a short series or prototype begins to generate real costs in a long production cycle: shortages, corrections, downtime and accelerated tool wear. Therefore, reducing costs in serial production is not simply a matter of increasing parameters or shortening cycle times, but of consciously designing a stable process. In practice, the cheapest part is not the one made the fastest, but the one that is produced repeatedly – without quality surprises and unplanned interventions during the series. Serial production in CNC machining as a system of interrelated technological decisions Serial production is a system in which each decision affects subsequent stages: from the selection of semi-finished products, through the machining strategy, to quality control. The larger the scale of production, the more pronounced the effects of even minor errors at the planning stage. Production scale and process variability As the number of parts increases, the importance of process variability increases. Minimal differences in tool wear, temperature or clamping rigidity begin to accumulate. A process that looks correct for the first 20 pieces may generate deviations outside the tolerance after several hundred. The balance between performance and stability One of the key challenges is to find a balance between aggressive efficiency and stability. Overly conservative parameters increase the unit cost, but overly aggressive ones lead to: Cost optimisation in series production should always start with stability and only then move on to cycle time reduction. A poorly chosen machining strategy, an inappropriate tool or failure to take process tolerances into account result in costs that only become apparent over time. In series production, such errors are repeated hundreds or thousands of times. Machine park and tools in the context of production predictability In series production, the predictability of machine operation is crucial. Differences in axis rigidity, spindle condition or feed dynamics have a direct impact on quality. Tool wear is one of the main factors destabilising the process. If it is not monitored and planned, it leads to uncontrolled dimensional changes. An effective mass production strategy assumes: A well-chosen machining strategy reduces cutting force fluctuations and stabilises the process. Constant tool engagement, smooth entries and exits, and avoiding sudden load changes are often more important than maximum instantaneous performance. Quality control in CNC series production as an element of optimisation Quality control in series production should not be treated solely as a tool for detecting defects. Its main purpose is to quickly identify trends and prevent problems from escalating. Insufficiently frequent inspections mean the risk of producing a large batch of non-compliant parts. Effective quality control in CNC includes measurements of the first pieces after retooling, periodic checks during the series, and analysis of trends, not just limit values. This makes it possible to react before deviations translate into real losses. Summary Serial production in CNC machining is a process in which costs and quality are closely linked. Attempts to reduce costs without understanding the stability of the process usually lead to the opposite of the intended effect. The greatest potential for optimisation lies in conscious planning: the selection of machining strategies, tools, machines and quality control systems.

Cooling and chip removal in CNC machining – impact on process stability and quality

In CNC machining, it is very easy to focus solely on cutting parameters, tool geometry or machine accuracy. However, in practice, cooling and chip removal often determine whether the process remains stable throughout the entire production series. These are not auxiliary elements. They are an integral part of the process that affects temperature, tool wear, material behaviour and quality repeatability. Especially with long series or difficult geometries, a lack of control in this area quickly leads to problems that are difficult to link to a single specific cause. Cooling and chip removal as elements of CNC machining process stability CNC process stability means that, with constant parameters, we obtain a predictable result: the same dimensions, the same surface quality and similar tool wear. For this to be possible, the conditions in the cutting zone must be as constant as possible. The coolant is responsible for heat removal, friction reduction and chip transport. Chip removal prevents them from coming into contact with the tool and workpiece again. If any of these elements ceases to function properly, the process begins to “break down” – often gradually and imperceptibly. The role of temperature and chips in long-term process stability Chips remaining in the machining zone are one of the main sources of process variability. They can be re-cut, wedge between the blade and the material, or block the coolant flow. As a result, the temperature rises locally and the cutting forces change. This may not be noticeable in a short series. In long series production, however, it leads to a gradual deterioration in surface quality, an increase in dimensional variation and a reduction in tool life. The influence of cooling conditions on the behaviour of tools and the material being machined Stable cooling maintains predictable blade operating conditions. With insufficient or uneven cooling, the tool operates at a higher temperature, which promotes accelerated wear, microcracks on the edge and the formation of build-up. The workpiece material also reacts to temperature changes. Especially in aluminium and alloy steels, changes in cooling conditions affect friction, chip formation and surface quality. Thermal load on tools and machining repeatability A tool subjected to variable thermal loads wears unevenly. This means that even with the same programme parameters, the actual cutting conditions change over time. In practice, this manifests itself in dimensional drift or the need for corrections during a series. Constant cooling conditions allow tool wear to be kept within a predictable range and replacement to be planned in a controlled manner, rather than only after deficiencies have arisen. Material deformation resulting from improper cooling An increase in temperature in the cutting zone causes the material to expand. After cooling, the part returns to its original dimensions, which can result in geometric errors. This problem is particularly noticeable with thin-walled components, long workpieces and precision fits. Uneven cooling also promotes the formation of internal stresses, which may only become apparent after machining or during further operations. Chip removal in CNC machining as a process risk factor Accumulated chips can periodically block the cutting edge, causing load spikes and momentary vibrations. Each such disturbance accelerates tool wear and reduces the stability of the entire process, even if the parameters in the programme remain unchanged. Chips as a cause of micro-damage to surfaces Chips moving across the machined surface act as an abrasive material. They cause scratches, pitting and local damage that is difficult to remove during the finishing stage. The problem is exacerbated in deep pockets and enclosed spaces. The influence of workpiece geometry on chip behaviour during the process The geometry of the workpiece largely determines how chips are evacuated. Narrow channels, deep pockets or sharp corners require a conscious choice of cooling strategy, tools and cutting direction to avoid chip accumulation. Cooling and chip control strategies in the context of mass production stability In series production, it is crucial to maintain identical cooling conditions for each workpiece. This includes not only the pressure and direction of the coolant, but also its cleanliness and stability of parameters over time. Even slight changes can lead to quality differences within the same series. The relationship between cooling strategy and process predictability A well-chosen cooling and chip removal strategy increases process predictability. It facilitates the planning of cycle times, tool changes and quality control. As a result, it reduces the number of downtimes and unplanned adjustments. Summary Cooling and chip removal in CNC machining are key factors in process stability and product quality. Their role increases with the length of the series, the complexity of the geometry and the quality requirements. Conscious design of these elements allows you to reduce variability, improve repeatability and increase process safety. It is these details that determine whether CNC machining remains stable not only on the first, but also on the thousandth detail.

Summary of 2025 at SIM Gdynia

The year 2025 was a time of intense work, important decisions, and achievements that strengthened SIM Gdynia’s position as a trusted partner in the field of precision CNC machining throughout Europe. We implemented new projects, won prestigious awards, expanded our machine park, supported the local community, and broadened our expertise in sectors of strategic importance to the country. We invite you to take a short journey through the past months and review the most important events that shaped this intense year—and there were many of them. OTIF95 Award from the KION Group—confirmation of reliability One of the key events of 2025 was our winning of the OTIF95 Supplier Performance Award, presented by the KION Group for timely and complete deliveries. This award confirms that our production processes, logistics, and quality standards meet the expectations of a global leader in the intralogistics industry. The components we manufacture support the operation of advanced transport and storage systems around the world. The OTIF95 award is a credit to the entire SIM Gdynia team and proof that we consistently maintain the highest reliability of delivery. Partnership with KS Chwaszczyno – we invest in young athletes In 2025, we signed an official partnership agreement with the Chwaszczyno Sports Club. We believe that the strength of industry lies not only in technology, but also in the community in which we operate. This is an important initiative for us – we invest in the development of young people, passion, discipline, and values that are consistent with the culture of SIM Gdynia. ITM INDUSTRY EUROPE 2025 trade fair – investments and new directions for development On June 4, the SIM Gdynia team participated in the ITM INDUSTRY EUROPE fair in Poznań – one of the most important events presenting Industry 4.0 trends and technologies. 4 czerwca reprezentacja SIM Gdynia uczestniczyła w targach ITM INDUSTRY EUROPE w Poznaniu – jednym z nDuring the fair, we analyzed solutions in the field of automation, robotics, and advanced CNC technologies, and held a series of talks with production system suppliers. This event confirmed that we will consistently pursue digitization, automation, and the development of technological competencies. Obtaining a license from the Ministry of Internal Affairs and Administration – a new chapter for SIM Gdynia On July 4, we obtained a license from the Ministry of Internal Affairs and Administration (No. B-090/2025) to manufacture and trade in technologies for military and police use. Second Forbes award – confirmation of stable year-on-year growth For the second time in a row, we were among the companies honored at the Forbes Family Business Forum 2025. For us, this is a special confirmation of stable growth, consistency in the implementation of our strategy, and the effective combination of family tradition with modern technology. We have been developing as a family business since 1978, and today, with over 100 CNC machines and specialization in sectors requiring the highest precision, we are one of the most trusted subcontractors in the region. We dedicate this award to both our team and our customers. Without the trust of our partners and the work of our entire staff, this success would not have been possible. MSPO 2025 – a strong presence in the defense sector The MSPO 2025 trade fair in Kielce is the largest defense industry event in Central and Eastern Europe. This year’s edition was special because, for the first time, we presented ourselves as a company with a license from the Ministry of Internal Affairs and Administration for the production of military and defense technologies. We would like to thank everyone who visited our stand. Numerous conversations and interest in our offer confirmed that SIM Gdynia’s competencies meet the current needs of the security and defense sector. Summary The year 2025 was a challenging time for us, but above all, it was full of evidence that we are consistently moving in the right direction. The awards we have won, our expanded scope of activity, technological investments, and new partnerships have strengthened our position as a stable, modern company ready for new challenges. We would like to thank our customers, partners, and the entire team for their trust and for building our success together. We are entering the new year with energy, plans, and the conviction that the best projects are still ahead of us.

Holiday and New Year’s greetings from SIM Gdynia

The end of the year is a time for the entire manufacturing industry to take stock, reflect, and make plans for the coming months. At SIM Gdynia, this is a moment when we pause for a moment to express our gratitude to everyone who contributes to our projects and development – our customers, business partners, and our team. On the occasion of the upcoming Christmas and New Year, we would like to share a few words of thanks and best wishes. Wishes for our contractors and business partners Thank you for your cooperation, trust, and joint projects in the past year. Each order, consultation, and conversation was not only a professional challenge for us, but also confirmation that our work truly supports your technological and business goals. We wish you a peaceful and joyful Christmas. May this time bring you respite and the opportunity to recharge your batteries before the challenges ahead. In the New Year 2025, we wish you stable projects, effective decisions, and partnerships that will strengthen your market advantage. May each stage of your activities bring satisfaction, security, and measurable results. Wishes for the SIM Gdynia team We would like to thank all our employees for their professionalism, responsibility, and daily work, which allows us to fulfill even the most demanding orders. Your knowledge, experience, and commitment build the quality for which we are known. We wish you a peaceful and warm Christmas with your families. May it be a time of rest and regeneration. In 2025, we wish you health, prosperity, and satisfaction from your daily duties. May the coming year bring a sense of growth and stability on which to build further professional and personal successes.

What is High Speed Machining (HSM)? A guide to high-speed CNC machining from the basics

For several years now, high-speed CNC machining has been one of the areas that has had the greatest impact on the efficiency of modern manufacturing plants. With the development of high-speed machines, new tool geometries, and advanced CAM systems, an approach known as High Speed Machining (HSM) has emerged. It is not just a matter of “working faster.” HSM changes the way we think about process preparation, tool load planning, and path control—especially where short cycle times, stability, and high surface quality are required. That is why it is increasingly becoming the standard in industries working with demanding materials and complex geometries. In the rest of this article, we describe the most important principles of HSM, how the process is carried out, and the areas where this method yields the most measurable results. High Speed Machining – basic definition In the simplest terms, High Speed Machining (HSM) is a machining strategy in which: In many industrial applications, HSM is considered to be working at spindle speeds above 10,000 rpm and cutting speeds ranging from several hundred to over 1,000 m/min (depending on the material and tool geometry). However, this is not a rigid limit – the key is the approach, i.e., high dynamics with a small, well-controlled chip cross-section. High-speed CNC machining vs. conventional machining In conventional machining, increasing productivity usually means more pressure – the cutting depth, tool engagement width, and cutting forces increase. This leads to increased loads on the spindle, the clamping device, and the workpiece itself. The temperature in the cutting zone rises and the chip has relatively long contact with the cutting edge. In high-speed CNC machining typical of HSM, the process is different: This approach works particularly well for complex 3D surfaces in parts such as molds and dies, in hardened materials, and for machining pockets and contours, where both productivity and surface quality are important. Tools, holders, and machines for HSM High Speed Machining requires a tool-holder-machine system that is capable of operating stably at high dynamics and high rotational speeds. The key elements are: The high dynamics of the entire process also make the quality of the workpiece clamping very important. Any inaccuracy in the fixture, lack of support, or looseness in the clamping can result in instability and reduced dimensional accuracy. Applications and benefits of High Speed Machining HSM is particularly popular in industries where a combination of complex geometry, high accuracy, and difficult materials is important: The main benefits are: Limitations and challenges of HSM High Speed Machining is not a universal solution for every workpiece and every machine. The main limitations include: Therefore, when implementing high-speed CNC machining, it is advisable to follow the recommendations of tool manufacturers and, where possible, use stability analyses to help select a spindle speed range that ensures smooth operation. Summary High Speed Machining (HSM) is a comprehensive approach to cutting – from the selection of the machine, tools, and holders, through path strategies, to parameter settings. When used correctly, high-speed CNC machining can significantly reduce manufacturing time, improve surface quality, and increase process stability, especially with demanding materials and complex geometries. However, the key to success is conscious implementation – with an assessment of the machine park, selection of the right details, and systematic improvement of parameters based on actual results, not just theoretical assumptions.

CNC machining of thin-walled parts – how to reduce vibrations and deformations?

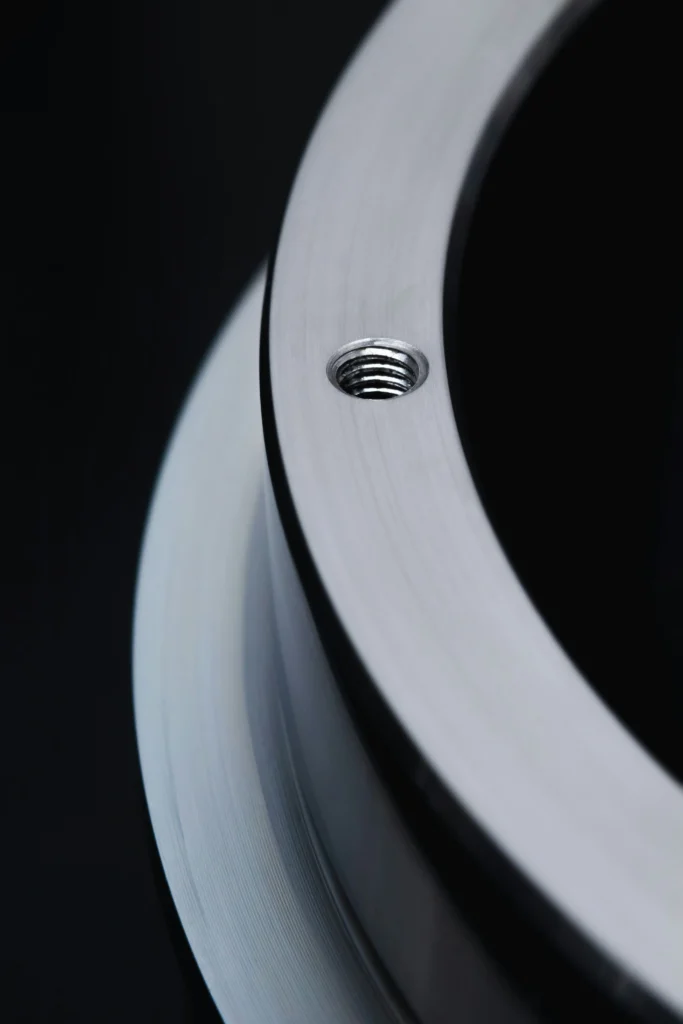

Thin-walled bodies, rings, slimmed-down housings – all these elements look inconspicuous, but technologically they can be a real challenge even for experienced contractors. Where a solid element remains stable, a thin wall begins to act like a membrane – it reacts with vibrations, deflection, and deformation when removed from its mounting. That is why CNC machining of thin-walled parts requires a completely different approach than standard milling or turning. Based on our more than 45 years of experience in CNC machining, we discuss the most important challenges associated with such geometries and practical methods for reducing vibrations and deformations – from machining strategies and tool selection to proper fixture preparation. We invite you to read on. Thin-walled parts – what does this mean in practice? In workshop practice, thin-walled elements are not assessed solely on the basis of their nominal wall thickness. Much more important is the ratio of wall height to wall thickness (H:T), which determines the stiffness and how the part will behave under cutting load. The higher this ratio, the greater the susceptibility to deformation. This is most easily seen in the behavior during machining: Thin-walled parts are typical in industries where designers strive to reduce weight: aerospace, energy, machinery, and automotive. Relieving the load on components reduces material wear and dynamic loads, but at the same time requires the machining technology to be able to ensure adequate rigidity and accuracy on components that are inherently flexible. This is why CNC machining of thin-walled components is a process carried out on components that are not designed to be rigid – and this is the main technological challenge. Where exactly do vibrations and deformations come from? In thin-walled components, it is not only low rigidity that is decisive, but also the way the material reacts to variable loads during cutting. In practice, three phenomena overlap, which can completely change the behavior of the part during machining. If we add to this the stresses generated during rough machining, the influence of temperature, and the limitations resulting from clamping, it is easy to understand why thin-walled components are so susceptible to geometric changes. Clamping – the foundation of CNC machining of thin-walled components Without the right tooling, even the best cutting parameters will not ensure a stable process. Thin-walled parts require full, even support – point clamps or grips in a single location can cause more deformation than the machining itself. Typical approaches to clamping include: Added to this is the issue of the tool — shortening the reach, using rigid holders, and eliminating backlash. The entire “fixture + holder + tool” system must work as a single, rigid block. Cutting strategies – lighter, more frequent, with control over allowances When CNC machining thin-walled parts, aggressive, deep passes almost always lead to vibrations and loss of geometry. An approach based on controlled, multi-stage machining with limited wall loading gives significantly better results. In practice, it is worth using: The goal is not to “remove material” quickly, but to consistently control deformation at every stage. Cutting parameters and tools – how to reduce cutting forces? In thin-walled components, it is crucial to limit lateral forces that directly cause deflection. This can be achieved on several levels: Cutting parameters Instead of one deep pass, several shallower passes with a smaller cutting width are used. In some cases, it is better to work at higher speeds with a smaller feed per tooth to avoid areas of instability. Tool geometry Sharp tools with a positive rake angle (“soft cutting”) generate less force than geometries designed for aggressive cutting. Milling cutters with variable tooth spacing or anti-chatter geometry help to dampen vibrations. Tool holders Hydraulic, heat-shrink, and vibration damping systems can dramatically improve stability at longer reaches. In practice, they are often a more cost-effective choice than lengthy attempts to stabilize the process with a standard holder. Summary – 5 rules for CNC machining of thin-walled parts For clarity, we have compiled the most important conclusions in a short checklist: In many cases, a certain level of deformation after release of the clamping is unavoidable. It is crucial to anticipate this phenomenon and take it into account in the machining plan, rather than correcting errors only in the final inspection.