Offer

CNC MACHINING

At SIM Gdynia, our specialty is CNC machining, executed with the utmost care. Our services are synonymous with precision, thanks to the use of more than 100 modern CNC machine tools. We offer a wide range of machining, from metals, including superduplex stainless steel, to plastics.

CNC Turning and Milling

We offer CNC turning with a range of diameters from 0.5 mm to 700 mm and lengths up to 2100 mm, and CNC milling with dimensions up to 3250 x 2000 x 1500 mm, including 5-axis machining.

We offer CNC turning with a range of diameters from 0.5 mm to 700 mm and lengths up to 2100 mm, and CNC milling with dimensions up to 3250 x 2000 x 1500 mm, including 5-axis machining.

Comprehensive Solutions

We offer complete solutions, from design to production, using an integrated CAD/CAM/CAE system.

We offer complete solutions, from design to production, using an integrated CAD/CAM/CAE system.

Specialized Machining

Gear cutting, thread grinding, and precision grinding of outside diameters.

Gear cutting, thread grinding, and precision grinding of outside diameters.

Technology and equipment

We use CNC machining centers, lathes that are fully robotized, with advanced technology from brands such as Makino, Mori Seiki, Okuma, Brother.

We use CNC machining centers, lathes that are fully robotized, with advanced technology from brands such as Makino, Mori Seiki, Okuma, Brother.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

MECHANICAL ASSEMBLIES

Mechanical assembly, carried out in accordance with the technical drawings provided by our customers, is our specialty. The experience and knowledge of our team of engineers and technicians with the technologies we use, translates into quality and accuracy of assembly.

Flexibility

Quality

Professionalism

Efficiency

Precision

Use of own and entrusted production elements

At SIM Gdynia, we work with both in-house manufactured components and parts supplied by our customers. Thanks to such flexibility, we are able to offer comprehensive assembly solutions, from the production of individual components to final assembly. We will meet a variety of requirements and specifications, so that the product you receive is of the highest quality.

Assembly according to the drawing

Each assembly project begins with a detailed analysis of the technical drawing provided by the customer. All components are assembled with precision, according to the specifications and requirements of the customer. Our assembly process is flexible and customized, ensuring that each component fits perfectly.

Use of normals in assembly

We use normals – standard components that ensure the consistency and efficiency of our assemblies. The use of normals allows for faster and more efficient assembly processes, while maintaining high quality and precision.

Our assembly process consists of several key steps

1

Analysis of

the Technical Drawing

A thorough understanding of the customer’s requirements.

the Technical Drawing

A thorough understanding of the customer’s requirements.

2

Selection of

Materials

Selection of appropriate materials and components.

Materials

Selection of appropriate materials and components.

3

Assembly

Precise assembly in accordance with the technical drawing.

Precise assembly in accordance with the technical drawing.

4

Quality

Control

Rigorous quality control procedures to ensure compliance with requirements.

Control

Rigorous quality control procedures to ensure compliance with requirements.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

FINISHING PRECESSES AND STORAGE

We offer a comprehensive range of finishing processes tailored to the precise requirements of our customers. Our advanced technologies and experience enable us to provide high-quality services, including deburring, peening, ultrasonic washing, impact marking and grinding. In addition, we provide safe and efficient storage of manufactured parts.

Finishing services

Stoning (Vibro Finisz)

Excellent for smoothing and improving the aesthetics of metal surfaces, it provides a uniform finish to each batch.

Excellent for smoothing and improving the aesthetics of metal surfaces, it provides a uniform finish to each batch.

Grinding

We specialize in precision grinding, ensuring perfect smoothness and required dimensional tolerances.

We specialize in precision grinding, ensuring perfect smoothness and required dimensional tolerances.

Cleaning in ultrasonic washers

Using ultrasound, we effectively clean even the smallest details, removing contaminants unattainable by traditional methods.

Using ultrasound, we effectively clean even the smallest details, removing contaminants unattainable by traditional methods.

Deburring

Our deburring services provide smooth and safe edges for every part.

Our deburring services provide smooth and safe edges for every part.

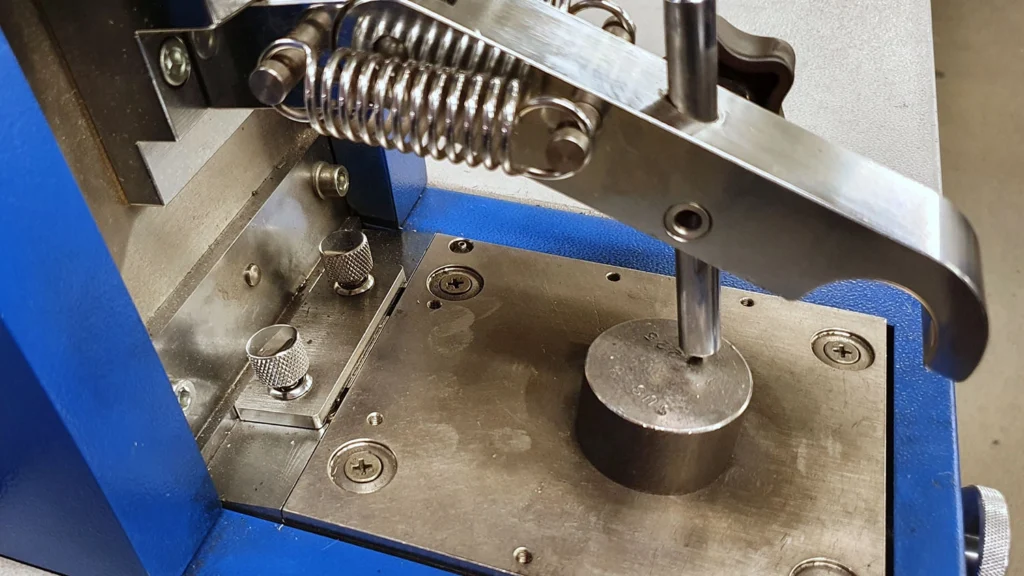

Impact marking

Our impact marking services guarantee permanent and legible markings on any part.

Our impact marking services guarantee permanent and legible markings on any part.

Part storage

Our secure and well-managed warehouses provide optimal conditions for the storage of manufactured parts. Regardless of size and specifications, we take care of each part by offering flexible storage solutions.

Our secure and well-managed warehouses provide optimal conditions for the storage of manufactured parts. Regardless of size and specifications, we take care of each part by offering flexible storage solutions.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

WELDING AND GRINDING

As supporting processes, we offer welding of most materials and grinding of outside diameters and threads. We offer welding services for small and large series of parts. We have a certified staff of welders. (Certificates in accordance with PN-EN ISO 9606-1)

Welding certificates:

- Our company is proud to be fully qualify according to EN / ISO 15614-1 and certify by Det Norske Veritas and Bureau Veritas with following welding method

- TIG-141

- MIG/MAG - 135/136

- Our welders are certified according to ISO 9606-1

- Our QC personnel are certified according to EN/ISO 9712

- We are under supervision of a fully certified IWE/IWI - Welding Engineer

Welding technologies

- MAG

- TIG

Welded materials

- stainless steel

- low-alloy steel

- We offer welding services of small and large series of details.

- We have a certified staff of welders.

- (certificates in accordance with PN-EN ISO 9606-1)

Thread grinding – module from 0.3 to 5.0

Grinding of external diameters from 5mm to 300mm

Grinding of external diameters from 5mm to 300mm

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

TESTING THE CHEMICAL COMPOSITION OF MATERIALS

We study the chemical composition of materials using innovative spectrometry techniques in industry. Our spectrometric services provide accurate and precise analysis of elemental composition.

SPECTROMAXx emission spectroscope: the core of our laboratory

Our advanced spectrometric laboratory uses the SPECTROMAXx emission spectroscope to perform precision testing of materials. This instrument allows us to accurately study the composition of metals, offering results with very high accuracy and repeatability.

Comprehensive chemical analysis of materials

Precise identification of the chemical composition of materials. Spectrometric analysis of materials: Testing of metals and other materials, providing detailed knowledge of their properties and composition.

LARGE AND SMALL SIZES

We offer CNC turning services of diameters from 0.5mm to 1100mm and lengths up to 1500mm.

We offer CNC milling services from the smallest to 2000mm x 1100mm x 900mm.

We accept workpieces from the smallest up to 1000kg for machining due to having lifting capacity in multiple machining slots and quality control rooms.

We offer CNC milling services from the smallest to 2000mm x 1100mm x 900mm.

We accept workpieces from the smallest up to 1000kg for machining due to having lifting capacity in multiple machining slots and quality control rooms.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

COATING AND ENHANCEMENT

We have a rich network of cooperators for enhancement and covering processes. See what we offer.

- electropolishing

- zinc plating

- powder coating and KTL

- anodizing (including hard anodizing)

- nitriding (including gas and plasma)

- nitrocarburizing

- hardening

- induction hardening

- phosphatizing

- sandblasting/blasting/shot blasting

- blackening

- nickel plating

- gilding/silver plating

- passivation

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

TEM DEBURRING

Thermal deburring. Removal of residual material, so-called burrs on the edges of the workpiece formed after various types of machining.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

CNC GEAR CUTTING

We offer CNC cutting of external gear tines up to 500mm diameter and module up to 10 and internal gear tines up to 400mm diameter and module 4-5.

Our realizations

Take a look at our gallery of projects, showing the wide range of our capabilities.

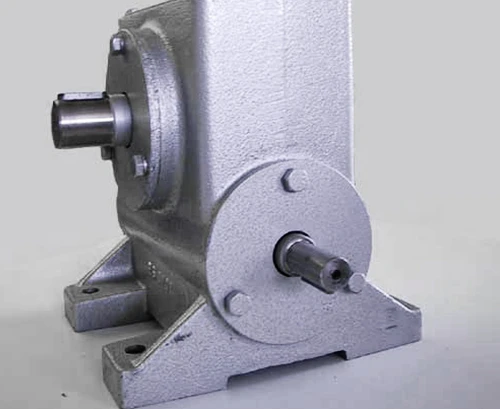

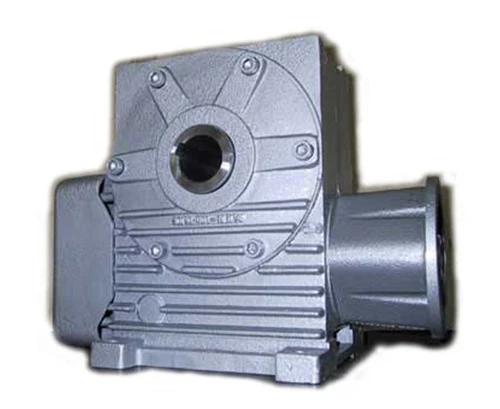

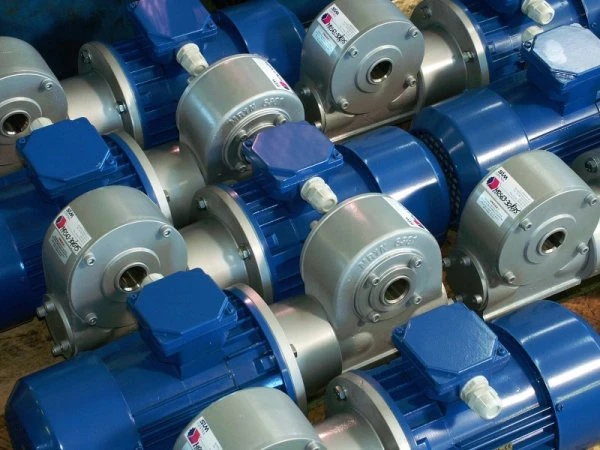

GEAR MOTORS

At SIM Gdynia, we sell high-quality reducers and geared motors, manufactured by our company. Our products are characterized by universal and specialized purpose, with emphasis on mechanization of poultry farms.

We offer a wide selection of gear motors, including:

All of these devices are manufactured on the basis of our geared motors, which can be additionally equipped with a metering system, limit switches and potentiometers integrated in the gearbox housing, at the special request of the customer.

Specializing in poultry farm mechanization

Our many years of experience enable us to manufacture components for poultry farm mechanization. In this regard, we offer:

- Manual and electric elevators for feed lines, watering lines and curtains

- Elevators for controlling air intakes

- Ridge drives

- Tilt flap drives

Innovation and customization

At SIM Gdynia, we constantly strive for innovation to ensure that our gearmotors meet even the most demanding standards. Our teams of engineers and technicians work on continuous product improvement to provide our customers with the best solutions.

High quality and reliability

Every gearmotor manufactured at SIM Gdynia undergoes rigorous quality testing to guarantee reliability and long life. We are proud of our reputation for producing high-quality, durable and efficient gearmotors. Our advanced technology and precise manufacturing processes create products that serve our customers for years, even under the most demanding operating conditions.

Why us?

SIM Gdynia is not only technology and experience, but also commitment to quality and customer satisfaction, which we mark at every step of our activity. We have quality certificates that prove our professionalism and attention to every detail. Our team are passionate people who treat each order individually, guaranteeing satisfaction and the highest quality of service.